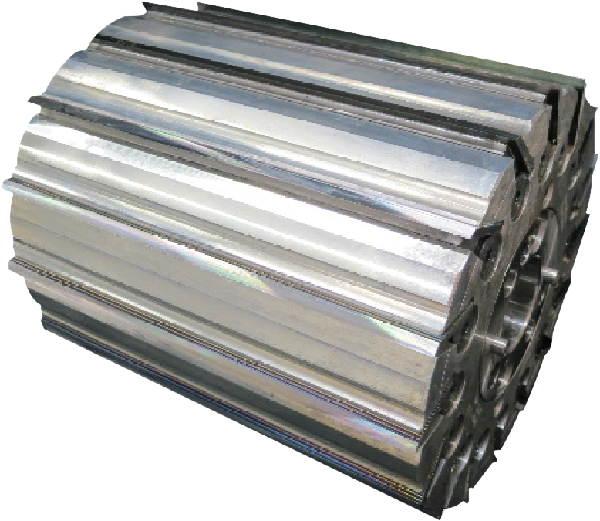

Raptor

The Raptor has quickly become a favorite among Kvarnstrands customers. It’s simplicity and fast mounting of the corrugated knives make it unique in the marketplace. With only two screws, the breakdown and set-up times are greatly reduced compared to conventional cutters. It also allows for getting more knives into the head diameter vs. conventional head offerings. Having no screw holes on the periphery means less cleaning is necessary after running the head.

Raptor Advantages

- The Heads are manufactured for corrugated back knives for better safety, tolerance and faster knife alignment

- With no screws in the heads periphery cleaning time is greatly reduced

- Having corrugated back knives allows for better extension in the head, equaling more regrinds per knife.

- Absolute best tolerances in the center bore and balancing provide for better spindle life.

- The conical pressure wedges further lock the knives during operation with centrifugal force during rotation.

- The double hydro sleeve ensures that the heads will not depressurize and spin during operation.

- Pressurization from either the end or the periphery.

Also available in Aluminum

There are unique advantages with cutter heads in aluminum.

- The weight is reduced by approximately 50% compared to steel.

- The light weight is helpful for the operators handling the tools.

- The light weight is better for the spindles and bearings in the machines.

- We always use serrated knives which makes the positioning of the knifes much easier and safer.